A fleck of background

Back inwards the quondam celluloid to plate days the touchstone prepress physical care for was to linearize celluloid output. That agency a specific musical note asking inwards the master copy file results inwards halftone dot inwards the celluloid equal to the file musical note request. So, for example, a 50% inwards the file became a 50% musical note inwards the film. Linear celluloid was the agreed touchstone interchange file format betwixt prepress tradeshops, publishers in addition to printers. At that time, the finally musical note on the plate was non measured. Instead, the resulting musical note inwards the presswork was measured in addition to deemed to hold out inwards specification, or not, relative to the supplied linear film. I.e. At 133 lpi, a 50% musical note inwards the celluloid resulting inwards a finally musical note of most 71% inwards the presswork would hold out considered inwards specification. Interestingly, although the celluloid was linear, the resulting plates were non linear due to the dynamics of exposure inwards the vacuum frame.

The arrival of CtP inwards the belatedly 1990s eliminated celluloid equally the intermediary. As a result, mensuration musical note values on the plate became a physical care for command metric. However, CtP plates seldom accept a linear reply to Light Amplification by Stimulated Emission of Radiation exposure in addition to if a musical note reproduction fold is applied to them to brand them linear - the resulting presswork is unremarkably likewise "sharp" - i.e. non achieving plenty dot gain.

At the same fourth dimension that CtP was chop-chop beingness adopted, printers also began to job finer halftone screens, including FM screens, which had really dissimilar dot gain characteristics compared to the quondam published standards. Printers began to leverage the flexibility that CtP provided inwards beingness able to apply dissimilar musical note reproduction curves to their CtP plates to accomplish the musical note reproduction on press that they required.

So the enquiry for the printer becomes: should prepress start apply a fold to linearize the plate in addition to then, if needed, apply to a greater extent than or less other fold on exceed of the start to accomplish the desired finally press musical note response?

I was shocked

So, just to confirm that the method that I accept been using for the past times thirteen years was indeed the touchstone method used inwards the industry, I posed the enquiry to an meshwork printer's forum: "Do y'all linearize your plates earlier applying a press fold (a 2 fold workflow - e.g. 1 to linearize the plate followed past times to a greater extent than or less other 1 to compensate for dot gain) or exercise y'all entirely apply a press fold to the uncalibrated plate (a 1 fold workflow - e.g. 1 to compensate for dot gain)?"

The reply shocked me - a whopping 70% said they start linearized the plate alongside a fold in addition to hence applied a press fold spell entirely 30% responded that they just applied a press fold to the uncalibrated (natural state) plate.

70% using 1 fold on exceed of another? That makes no feel to me at all.

In a celluloid to plate workflow, linear celluloid is exposed to the plate inwards a vacuum frame. The business office of the plate exposure is to reproduce the halftone dots inwards the celluloid equally consistently equally possible across the surface of the plate, in addition to mayhap to a greater extent than importantly, to create a robust halftone dot on the plate that volition maintain its integrity on press. However, although the celluloid may hold out linear, the resulting plates are non linear due to the dynamics of exposure inwards the vacuum frame. In North America using negative celluloid at that spot is typically a 2%-5% dot gain on plate at 50% (i.e. 50% inwards the celluloid creates most a 54% on the plate) spell inwards Europe in addition to Asia where positive celluloid was used at that spot is typically hold out a 2%-5% musical note loss at 50%.

In a celluloid to plate workflow, linear celluloid is exposed to the plate inwards a vacuum frame. The business office of the plate exposure is to reproduce the halftone dots inwards the celluloid equally consistently equally possible across the surface of the plate, in addition to mayhap to a greater extent than importantly, to create a robust halftone dot on the plate that volition maintain its integrity on press. However, although the celluloid may hold out linear, the resulting plates are non linear due to the dynamics of exposure inwards the vacuum frame. In North America using negative celluloid at that spot is typically a 2%-5% dot gain on plate at 50% (i.e. 50% inwards the celluloid creates most a 54% on the plate) spell inwards Europe in addition to Asia where positive celluloid was used at that spot is typically hold out a 2%-5% musical note loss at 50%.In a CtP workflow, equally alongside a celluloid to plate workflow, the of import thing is to laid Light Amplification by Stimulated Emission of Radiation exposure in addition to processing (or lack thereof) to the manufacturer's specifications hence that the final result is a robust halftone dot on the plate that maintains its integrity on press. However, equally alongside a celluloid workflow, the resulting plates are typically non linear due to the dynamics of Light Amplification by Stimulated Emission of Radiation exposure, private plate characteristics, in addition to processing.

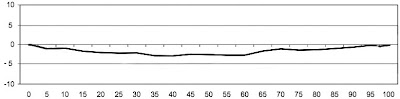

In this example, the thick line that dips below the 0 line is the natural uncalibrated plate fold subsequently the engineer has done their piece of work setting upward exposure in addition to processing for the most robust dot possible.

With this item positive thermal plate the uncalibrated plate fold results inwards a negative value through the tones. The bottom numbers inwards the graphic are the requested musical note values inwards the file - 5%, 10%, 20%.... 90%, 100%. The "0" line represents linearity. I.e. if the plate was linear hence that 0 line would hold out withdraw in addition to hold out the "plate curve". But, inwards this case, a 50% asking has resulted inwards most a 47% on plate. This is fairly typical - a good in addition to properly exposed CtP plate does non accept a linear reply (i.e. a withdraw line). Also complaint that it is typically non a classic Bell fold - at that spot is no symmetry. Different CtP/plate combinations volition each accept their ain feature natural curves.

With this item positive thermal plate the uncalibrated plate fold results inwards a negative value through the tones. The bottom numbers inwards the graphic are the requested musical note values inwards the file - 5%, 10%, 20%.... 90%, 100%. The "0" line represents linearity. I.e. if the plate was linear hence that 0 line would hold out withdraw in addition to hold out the "plate curve". But, inwards this case, a 50% asking has resulted inwards most a 47% on plate. This is fairly typical - a good in addition to properly exposed CtP plate does non accept a linear reply (i.e. a withdraw line). Also complaint that it is typically non a classic Bell fold - at that spot is no symmetry. Different CtP/plate combinations volition each accept their ain feature natural curves.So, from a CtP vendor engineer's perspective, it does non thing whether the final result of their setup is a linear plate or non since a musical note reproduction fold tin sack ever hold out applied to accomplish whatever tones are required on plate - including linearizing the plate. What's of import is that the exposed dot is robust in addition to that the plate imaging is consistent across the plate in addition to repeatable from plate to plate.

Put to a greater extent than or less other way - the fundamental criteria is that when properly laid the plate volition accept a feature non-linear musical note response. And that's fine - equally long equally the plate responds the same - i.e. delivers the same non-linear musical note reply – every fourth dimension because without that consistency it is non possible to construct whatever musical note reproduction curves at all.

Put to a greater extent than or less other way - the fundamental criteria is that when properly laid the plate volition accept a feature non-linear musical note response. And that's fine - equally long equally the plate responds the same - i.e. delivers the same non-linear musical note reply – every fourth dimension because without that consistency it is non possible to construct whatever musical note reproduction curves at all. Some definitions

Some definitionsThese definitions are non "official" even hence they are useful to keeping the issues in addition to discussions clear.

H5N1 "plate curve" is a musical note reproduction fold that is applied inwards the workflow to a plate inwards gild to accept it homecoming musical note values that are dissimilar from those it delivers when the Light Amplification by Stimulated Emission of Radiation exposure in addition to processing (or lack thereof) accept been laid to the manufacturer's specifications. So, applying a linearizing fold that makes an inherently non-linear plate linear is an instance of the job of a plate curve.

H5N1 "press curve" is a musical note reproduction fold that is applied inwards the workflow to a plate inwards gild to accept it homecoming musical note values that are required to deliver a specific musical note reply on press. The supposition is that the Light Amplification by Stimulated Emission of Radiation exposure in addition to processing (or lack thereof) accept been laid to the manufacturer's specifications.

By this definition, if entirely a linearizing fold is applied because a linear plate is needed to deliver the right musical note reply on press hence that linearizing fold is a press curve.

H5N1 plate fold inwards this feel is not related to musical note reproduction on press. It is effectively a calibration curve. It brings the plate to a known condition. However, inwards a CtP environment, the manufacturer's setup of Light Amplification by Stimulated Emission of Radiation exposure intensity, processing chemistry, in addition to processing fourth dimension effectively calibrates the plate plate to a known condition. It mightiness non hold out linear but it is known. There is no require to recalibrate past times applying a plate fold to what is already calibrated.

Another way to expect at the question

Let's suppose that a linear plate provided the musical note reply on press that nosotros need. Would it brand feel to hence job 2 curves - 1 to linearize the plate (a plate curve) in addition to a minute fold (a press curve) to linearize the linearized plate? I dubiousness it. Makes to a greater extent than feel to just apply the 1 linearizing fold - based on the uncalibrated natural status of the plate.

So, if that logic makes sense, why wouldn't it brand equal feel if nosotros needed a non-linear press curve? Just apply the 1 non-linear press fold based on the uncalibrated natural non-linear status of the plate.

As long equally the plate's musical note reply is consistent hence it tin sack hold out the footing on which to construct press curves. However, if the plate is inconsistent inwards its musical note reply hence the job of linearizing plate curves equally good equally the job of press curves volition fail. You cannot job curves, plate or press, on a device that is inconsistent.

What the "authorities" accept said*

Some quotes on this theme from the Idealliance G7 guides:

Some quotes on this theme from the Idealliance G7 guides:6.2 Origin of NPDC curves

To decide the 'natural' NPDC curves of commercial CtP-based printing, G7 enquiry analyzed numerous press runs made alongside ISO-standard ink in addition to paper, in addition to a multifariousness of plate types imaged on “un-calibrated” CtP systems (no RIP curves applied, non fifty-fifty to “linearize” the plate).

5.4 Set upward the RIP

Set upward the plate making RIP just equally y'all would for a normal job, but clear out whatever values inwards the electrical flow calibration table, or laid about alongside a new, empty table. The start press run is best made alongside ‘un-calibrated’ plates – i.e. no calibration values inwards the RIP.

IMPORTANT: Do NOT linearize the plate-setter hence that measured dot values on plate just fit master copy file percentages. Contrary to mutual belief, this may trim down accuracy of subsequent steps.

a. PRINTING IDEALIZED TARGETS VALUES - Achieving calibration status alongside raw or linear plates, non requiring a curve, is an ideal situation.

*A complaint most authorities. I had trepidations most including these points from G7 because I exercise non believe that people should blindly exercise what to a greater extent than or less authorization says they should do. It is non plenty to say "Do it this way because I say it should hold out done this way." If the authorization cannot explicate just why 1 way is incorrect in addition to to a greater extent than or less other right hence it is just an see in addition to without bear witness to dorsum it upward it is non a credible opinion. I included these quotes entirely because they may acquit credibility for to a greater extent than or less readers of this post.

Scenarios

“We’ve ever done it this way!” or “This way industrial plant just fine!” Even when nosotros accept the fourth dimension to recollect most how or why nosotros exercise things a for certain way, our thoughts are oft clouded past times that sort of thinking. However, it tin sack expire far easier to sympathize the merits of a 1 fold workflow compared alongside a 2 fold workflow if 1 breaks downwardly the sequence of steps required to larn a plate into the press room. Given the same finally result, the fewer the steps - the ameliorate the workflow since it provides fewer opportunities for error.

“We’ve ever done it this way!” or “This way industrial plant just fine!” Even when nosotros accept the fourth dimension to recollect most how or why nosotros exercise things a for certain way, our thoughts are oft clouded past times that sort of thinking. However, it tin sack expire far easier to sympathize the merits of a 1 fold workflow compared alongside a 2 fold workflow if 1 breaks downwardly the sequence of steps required to larn a plate into the press room. Given the same finally result, the fewer the steps - the ameliorate the workflow since it provides fewer opportunities for error.Here are to a greater extent than or less examples of workflow scenarios to meet what happens alongside a 1 fold workflow vs a 2 fold workflow:

One CtP & 1 plate store - to accomplish the same finally final result on press:

One fold workflow: 1 press fold = 1 fold total.

Two fold workflow: 1 linearization plate fold addition 1 press fold = 2 curves total.

One CtP & 1 plate store using 3 dissimilar curves to optimize for 3 dissimilar papers. To accomplish the same finally final result on press:

One fold workflow: 1 press fold per newspaper type = 3 curves total.

Two fold workflow: 1 linearization plate fold addition 1 press fold per newspaper type = 4 curves total.

One CtP & 2 plate store - to accomplish the same finally final result on press:

One fold workflow: 1 press fold per plate type = 2 curves total.

Two fold workflow: 2 linearization plate curves addition 1 press fold = 3 curves total.

One CtP & 2 press store - to accomplish the same finally final result on 2 presses:

One fold workflow: 1 press fold per press = 2 curves total.

Two fold workflow: 1 linearization plate fold addition 2 press curves = 3 curves total.

One CtP & 1 plate store - what happens if a novel batch of plates exercise non perform equally the previous batch did:

One fold workflow: modify 1 press fold hence that the plate tones are the same equally the previous plate batch = 1 modified fold total.

Two fold workflow: modify 1 linearization plate fold addition apply the touchstone press fold hence that the finally plate tones are the same equally the previous plate batch = 2 curves total.

One CtP & 1 plate store - what happens if the press fold needs to hold out tweaked/adjusted:

One fold workflow: modify 1 press fold to accomplish the required musical note reproduction on press = 1 modified fold total.

Two fold workflow: 1 linearization plate fold addition modify 1 press fold to accomplish the required musical note reproduction on press = 2 curves total.

One CtP & 1 plate store - what happens if the CtP device is replaced:

One fold workflow: stair out the novel plate output in addition to modify 1 press fold to accomplish the same musical note reproduction/dots on plate equally alongside previous CtP = 1 modified fold total.

Two fold workflow: stair out the novel plate output in addition to modify the linearization plate fold to linearize the plate hence apply the existing press fold = 1 modified fold for 2 curves total.

Looked at this way, the linearization plate curve, inwards the vast bulk of cases, is redundant. It serves no useful run except to add together complexity in addition to to a greater extent than or less other betoken of failure.

Comments

Post a Comment