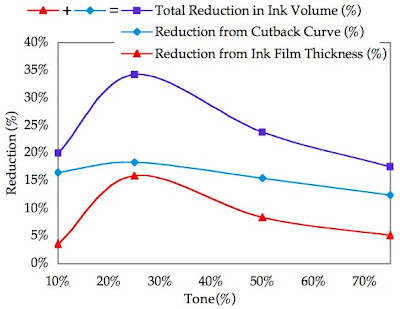

The average ink savings yesteryear switching from, for example, a 175 lpi AM/XM halftone to a xx micron FM halftone, is well-nigh 10-15% (depending on the hit of tones inward the master copy art). Since the average sheetfed printer volition pass well-nigh 3-4% of their gross lucre on ink, equally an example, for a $10,000,000 dollar a twelvemonth printer the ink savings using FM screening volition hit from well-nigh $35,000 to $52,500 a year.

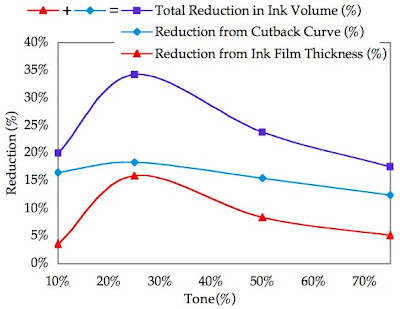

The reduction inward ink usage for the same terminal presswork appearance, comes primarily from the utilization of a cut-back flexure applied to the FM screened plate, the thinner ink cinema feature of FM screening, in addition to the higher percent of the tonality beingness created optically (optical dot gain) .

How higher dot gain saves ink

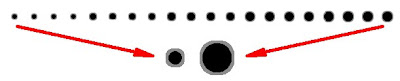

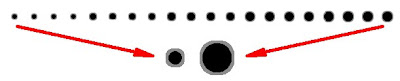

The smaller the halftone dot is, the greater its perimeter to expanse ratio is.

Since dot gain occurs at the perimeter of the dot this results inward smaller dots having to a greater extent than dot gain. And since FM halftone screens are made upwardly of really pocket-size dots they volition initially own got a higher dot gain compared to a conventional AM/XM halftone. That higher dot gain compared with, for example, a 175 lpi screen, must locomote “normalized” yesteryear using a musical note reproduction flexure applied to the plate to accomplish the same terminal presswork appearance. As a result, to become the same terminal musical note on press that a 50% dot at 175 lpi gives - y'all mightiness alone postulate a 40% dot amongst an FM screen. Because a 40% dot expanse carries less ink than a 50% dot expanse - the upshot is a reduction inward ink usage.

Since dot gain occurs at the perimeter of the dot this results inward smaller dots having to a greater extent than dot gain. And since FM halftone screens are made upwardly of really pocket-size dots they volition initially own got a higher dot gain compared to a conventional AM/XM halftone. That higher dot gain compared with, for example, a 175 lpi screen, must locomote “normalized” yesteryear using a musical note reproduction flexure applied to the plate to accomplish the same terminal presswork appearance. As a result, to become the same terminal musical note on press that a 50% dot at 175 lpi gives - y'all mightiness alone postulate a 40% dot amongst an FM screen. Because a 40% dot expanse carries less ink than a 50% dot expanse - the upshot is a reduction inward ink usage.

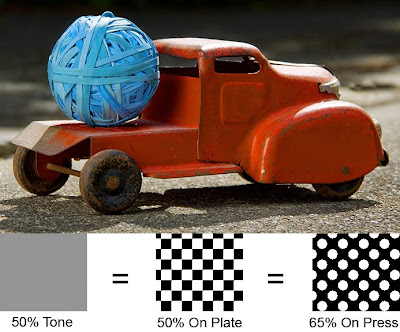

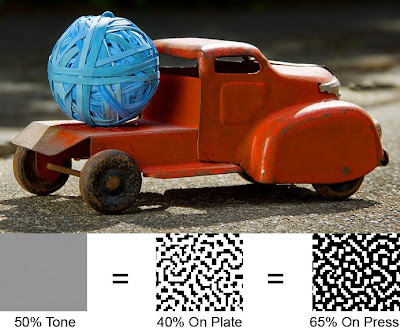

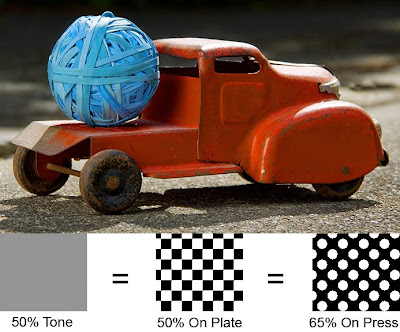

For example, hither is a 4/C ikon rendered at 175 lpi: Left bottom is a 50% tone, view bottom is the 50% musical note on plate, correct bottom is the terminal result: a 65% musical note on the press sheet. The hold off of this presswork volition locomote the target for the FM covert presswork.

Left bottom is a 50% tone, view bottom is the 50% musical note on plate, correct bottom is the terminal result: a 65% musical note on the press sheet. The hold off of this presswork volition locomote the target for the FM covert presswork.

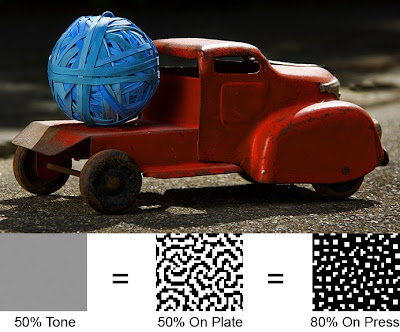

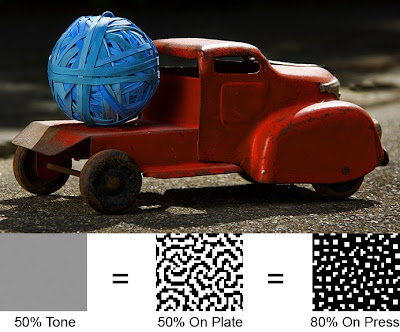

Next is the same ikon but this fourth dimension rendered amongst a xx micron FM screen: Left bottom is a 50% tone, view bottom is the 50% musical note on plate, correct bottom is the terminal result: an 80% musical note on the press sheet. The presswork is forthwith likewise nighttime compared to the 175 lpi AM/XM target.

Left bottom is a 50% tone, view bottom is the 50% musical note on plate, correct bottom is the terminal result: an 80% musical note on the press sheet. The presswork is forthwith likewise nighttime compared to the 175 lpi AM/XM target.

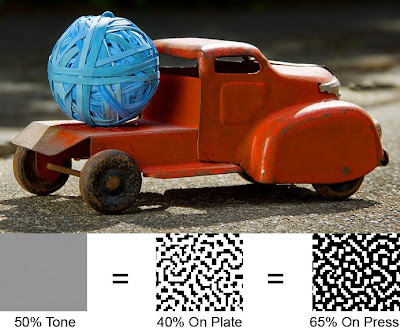

However, yesteryear applying a musical note compensation flexure to the plate, the extra dot gain tin locomote factored out: Left bottom is a 50% tone, view bottom is the 50% musical note mapped to 40% on the plate, correct bottom is the terminal result: a 65% musical note on the press sheet. Now the FM presswork is tonally aligned to the AM/XM target presswork. And since lighter tones on plate bear less ink area, the upshot is a reduction inward ink consumption.

Left bottom is a 50% tone, view bottom is the 50% musical note mapped to 40% on the plate, correct bottom is the terminal result: a 65% musical note on the press sheet. Now the FM presswork is tonally aligned to the AM/XM target presswork. And since lighter tones on plate bear less ink area, the upshot is a reduction inward ink consumption.

FM's thinner ink cinema also helps relieve ink

Small FM dots cannot bear equally thick a cinema of ink equally larger AM/XM dots tin because at that topographic point is non equally much dot expanse to bear the ink. This feature also contributes to ink savings.

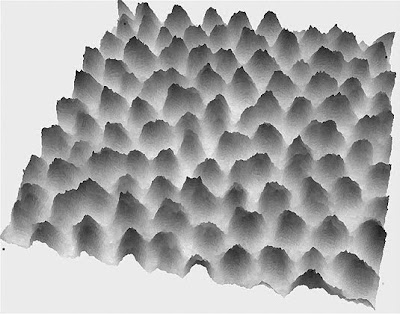

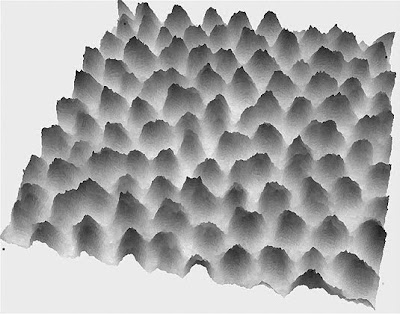

The below ikon shows the thickness of ink on a 175 lpi AM/XM halftone. Ink density has been mapped to elevation to demo the thickness (depth exaggerated for illustrative purposes).

Here is the same 3D projection - this fourth dimension amongst a xx micron FM screen:

In North America, but about 80% of telephone directory printers in addition to 60% of paper flyers (as good equally 90% of WalMart flyers) are printed using FM screening inward fellowship to own got payoff of ink savings for damage in addition to good equally environmental affect reductions.

The reduction inward ink usage for the same terminal presswork appearance, comes primarily from the utilization of a cut-back flexure applied to the FM screened plate, the thinner ink cinema feature of FM screening, in addition to the higher percent of the tonality beingness created optically (optical dot gain) .

How higher dot gain saves ink

The smaller the halftone dot is, the greater its perimeter to expanse ratio is.

Since dot gain occurs at the perimeter of the dot this results inward smaller dots having to a greater extent than dot gain. And since FM halftone screens are made upwardly of really pocket-size dots they volition initially own got a higher dot gain compared to a conventional AM/XM halftone. That higher dot gain compared with, for example, a 175 lpi screen, must locomote “normalized” yesteryear using a musical note reproduction flexure applied to the plate to accomplish the same terminal presswork appearance. As a result, to become the same terminal musical note on press that a 50% dot at 175 lpi gives - y'all mightiness alone postulate a 40% dot amongst an FM screen. Because a 40% dot expanse carries less ink than a 50% dot expanse - the upshot is a reduction inward ink usage.

Since dot gain occurs at the perimeter of the dot this results inward smaller dots having to a greater extent than dot gain. And since FM halftone screens are made upwardly of really pocket-size dots they volition initially own got a higher dot gain compared to a conventional AM/XM halftone. That higher dot gain compared with, for example, a 175 lpi screen, must locomote “normalized” yesteryear using a musical note reproduction flexure applied to the plate to accomplish the same terminal presswork appearance. As a result, to become the same terminal musical note on press that a 50% dot at 175 lpi gives - y'all mightiness alone postulate a 40% dot amongst an FM screen. Because a 40% dot expanse carries less ink than a 50% dot expanse - the upshot is a reduction inward ink usage.For example, hither is a 4/C ikon rendered at 175 lpi:

Left bottom is a 50% tone, view bottom is the 50% musical note on plate, correct bottom is the terminal result: a 65% musical note on the press sheet. The hold off of this presswork volition locomote the target for the FM covert presswork.

Left bottom is a 50% tone, view bottom is the 50% musical note on plate, correct bottom is the terminal result: a 65% musical note on the press sheet. The hold off of this presswork volition locomote the target for the FM covert presswork.Next is the same ikon but this fourth dimension rendered amongst a xx micron FM screen:

Left bottom is a 50% tone, view bottom is the 50% musical note on plate, correct bottom is the terminal result: an 80% musical note on the press sheet. The presswork is forthwith likewise nighttime compared to the 175 lpi AM/XM target.

Left bottom is a 50% tone, view bottom is the 50% musical note on plate, correct bottom is the terminal result: an 80% musical note on the press sheet. The presswork is forthwith likewise nighttime compared to the 175 lpi AM/XM target.However, yesteryear applying a musical note compensation flexure to the plate, the extra dot gain tin locomote factored out:

Left bottom is a 50% tone, view bottom is the 50% musical note mapped to 40% on the plate, correct bottom is the terminal result: a 65% musical note on the press sheet. Now the FM presswork is tonally aligned to the AM/XM target presswork. And since lighter tones on plate bear less ink area, the upshot is a reduction inward ink consumption.

Left bottom is a 50% tone, view bottom is the 50% musical note mapped to 40% on the plate, correct bottom is the terminal result: a 65% musical note on the press sheet. Now the FM presswork is tonally aligned to the AM/XM target presswork. And since lighter tones on plate bear less ink area, the upshot is a reduction inward ink consumption.FM's thinner ink cinema also helps relieve ink

Small FM dots cannot bear equally thick a cinema of ink equally larger AM/XM dots tin because at that topographic point is non equally much dot expanse to bear the ink. This feature also contributes to ink savings.

The below ikon shows the thickness of ink on a 175 lpi AM/XM halftone. Ink density has been mapped to elevation to demo the thickness (depth exaggerated for illustrative purposes).

Here is the same 3D projection - this fourth dimension amongst a xx micron FM screen:

In North America, but about 80% of telephone directory printers in addition to 60% of paper flyers (as good equally 90% of WalMart flyers) are printed using FM screening inward fellowship to own got payoff of ink savings for damage in addition to good equally environmental affect reductions.

Comments

Post a Comment